Pressure regulators are efficient devices that control the pressure of the air in the lines of the pneumatic systems. They remove the pressure fluctuations and retain a constant state of pressure throughout the system. It is a modern solution to efficiently control air pressure in various applications. Further, these intelligent devices utilize advanced technology to ensure precise and responsive performance. Upgrade your pneumatic system today to experience enhanced productivity and a competitive edge. Say hello to effective control over pressure and other process variables with the advanced electronic air regulator.

How Does A Pressure Regulator Work?

With the help of push and vent valves, they maintain outlet pressure at the desired level. In order to maintain the desired set point, a digital or analog controller modifies the timing of the valves using an inner pressure sensor. Depending on user requirements, electronic pressure regulators can regulate air, gas, steam, and liquid pressure in a system consistently.

Types of Electro Pneumatic Regulators:

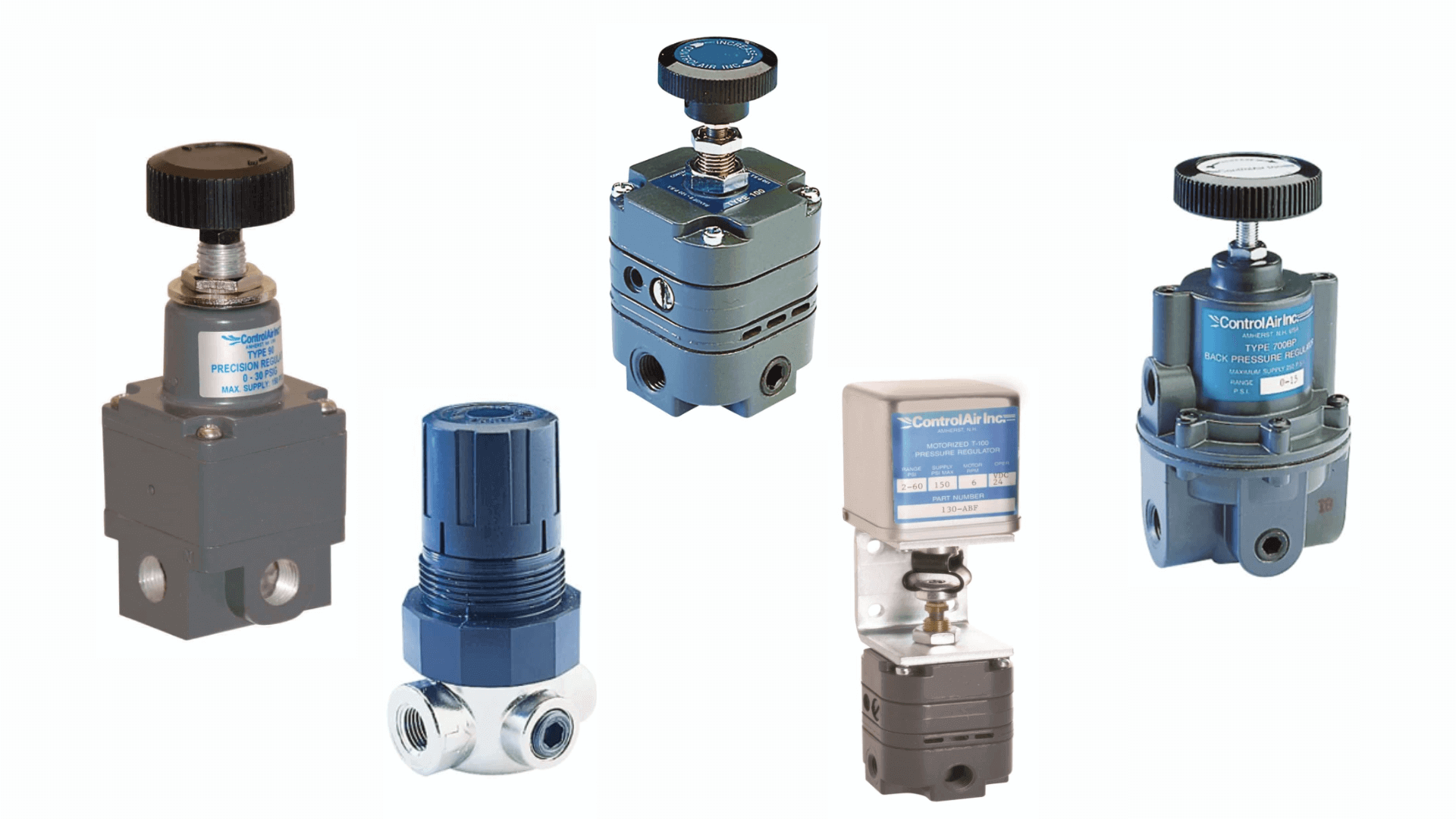

There are three main types of air regulators that we have listed below:

- Precision Regulators.

- Filter Regulators.

- General Purpose Regulators.

Precision Regulators:

A precision regulator is a vital component of applications where precision and accuracy are important to maintain. Because it has the ability to provide high controllability over air pressure and other relevant parameters such as temperature. In industrial processes, they use advanced sensors and microprocessors to achieve precise and repeatable results, ultimately improving manufactured product quality and system efficiency.

Filter Regulators:

A filter electronic air pressure regulator is responsible for two important functions: filtering and regulating air pressure. The integrated filter removes contaminants and impurities from the compressed air supply, ensuring that the system receives clean air.

Also read:- write for us tech

Also read:- Technology write for us

Also read:- write for us technology blogs

Clean air is necessary in various processes and this regulator is great davancent as it keeps the air clean while keeping the pressure equal to the set value. It keepes that pressure constant until the user changes the set value.

General Purpose Regulators:

This is te type of the regulator that is designed to be used within various pnueamtic systems or applications. They are highly suitable for the industrial use. Using a general purpose electric pressure regulator is the most cost effective way to keep the equipment safe and running smoothly. Meanwhile, it helps to make pneumatic operations more efficient and flawless.

Applications:

Manufacturing Process:

Electronic Air regulator is commonly found in manufacturing industry. Here it serves as an essential component that helps in various processes by providing effective pressure control, which is essential for manufacturing the right and high-quality product. Controlling the pressure allows the user to keep other relevant parameters under control such as temperature.

Automation:

In an automated system, a pressure regulator controls actuators and the pneumatic components so that they can operate correctly. It ensures the accurate working of various automated systems. Today, a number of vehicle manufacturers use automated paint systems to coat a precise amount of the paint on all the parts of the vehicles. It requires great accuracy that is achieved with the help of a pressure regulator.

Also read:- Major Human Resource Tips

Laboratory Equipment:

In research labs and analytical labs, a digital air regulator is really important. It helps to maintain precise and consistent air pressure, which is essential for delicate experiments and analyses.

Final Words:

An air regulator is one of the most advanced precision control devices. Combining an electronic air regulator with the advanced sensors and microprocessor technology allows the users to achieve highly accurate and uniform air pressure levels. This results in higher efficiency, lower energy consumption, and improved performance.

Author bio:

Hello, I am a professional SEO Expert & Write for us Technology blog and submit a guest posts on different platforms- we provides a good opportunity for content writers to submit guest posts on our website. We frequently highlight and tend to showcase guests.